Inspecting structures – replication

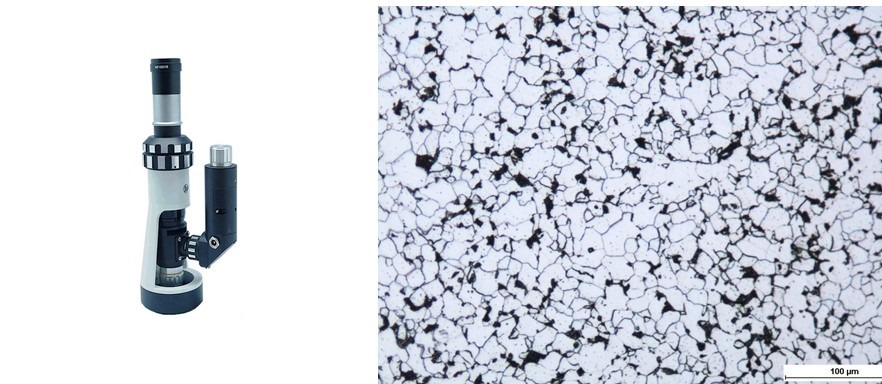

The goal of a metallographic inspection is to determine the structure of metals and metal alloys. These inspections can be carried out directly on the object. The analyzed surface is grinded and polished to obtain the so-called metallographic microsection. Surface is then covered with a special plastic film, which replicates the topography of material’s surface. This kind of testing is often used to determine changes in materials working under creep conditions or to confirm that thermal treatment was performed properly.

The specific method of execution is selected case-by-case, depending on the qualities of tested objects. Methods based on acoustic or ultrasonic emissions, particularly those involving surface Lamba waves, are used to detect damages in thin-walled and plate structures.

Our company’s complex laboratory equipment has all the required certifications and is trusted by Poland’s Technical Inspection Authority.